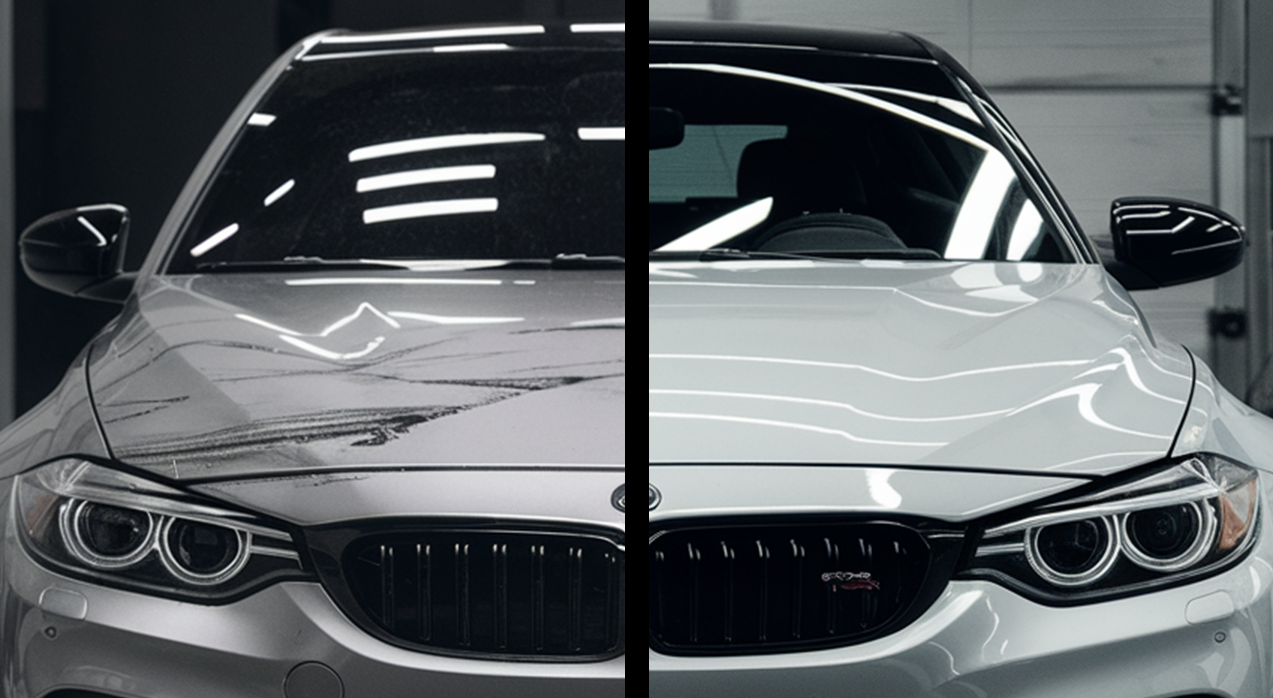

Innovative Self-Healing Technology

FLEXA PPF's advanced and unique coating technology automatically heals by heat in the event of a scratch or damage. The molecular structure of the film reacts to heat to repair the damaged area and completely restores the surface.

AEGIS

AEGIS